Well 7 and Well 8, known as the South Street Wells, are located in the southern end of the water system and supply water to the District’s Low Pressure Zone. These wells were installed in 1988 and pump a combined total of approximately 300 gallons per minute into the distribution system.

The wells were removed from service in 2021 after elevated levels of arsenic were detected exceeding the Massachusetts maximum contaminant level (MCL) of 10 parts per billion (ppb). The wells have remained off-line since the detect, other than to pump to waste for the pilot testing.

In 2021, the District also tested the South Street Wells for Per- and Polyfluoroalkyl Substances (PFAS). While the levels of detected PFAS are below the Massachusetts PFAS6 MCL, the concern is that the levels could increase. Additionally, the level of PFOA in each well is greater than the proposed USEPA MCL of 4 ppt with approximately 5 ppt in Well 7 and 16 ppt in Well 8.

A pilot study was conducted in 2022. The results of pilot testing indicated that the use of pressure filtration with GreensandPlus and anthracite media would be successful in removing arsenic. Additionally, the pilot test confirmed granular activated carbon (GAC) successfully removed PFAS from the water supply.

The District’s consulting engineer designed a treatment plant and the project was competitively bid by qualified contractors. District was awarded a $12.24 million dollar loan for the construction of the plant through the Massachusetts Drinking Water State Revolving Fund Program administered by MassDEP with joint funding from the USEPA.

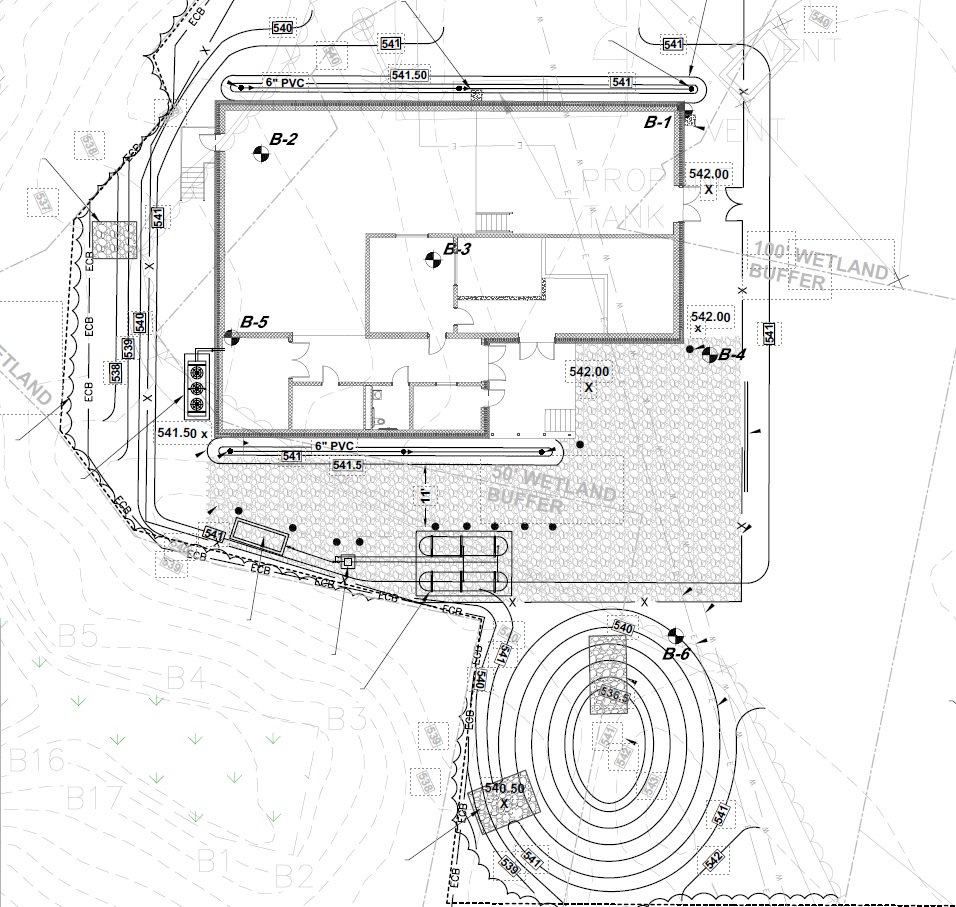

The proposed facility will be approximately 4,150 square feet in size and located adjacent to the existing pump station. The floor plan assumes construction of a masonry block structure with split face CMU exterior similar to the District’s existing filtration facilities. The treatment equipment will include three 9-ft diameter GreensandPlus filters, two 10-ft diameter PFAS removal contactors, chemical feed systems for potassium hydroxide, ferric chloride, chlorine gas, sodium bisulfite and blended phosphate. and space for control/lab room, a restroom and storage. Filter backwash residuals will be handled in a below floor basin, with jet mixing system and pumps to dispose of entire backwash to the sewer system. Construction is planned to start in July, 2025 with an expected completion date of December, 2026.